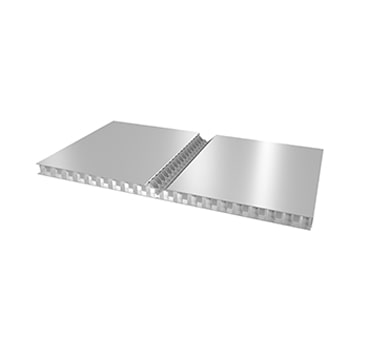

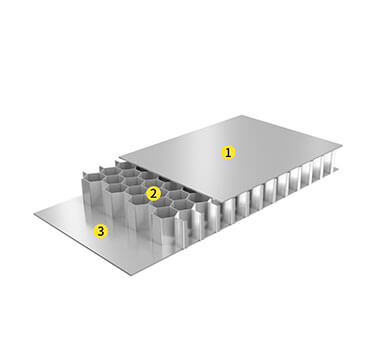

Aluminum honeycomb panels consists of two layers of aluminum sheets and aluminum honeycomb core in between. This sandwich structure is bonded by thermoplastic adhesive films to form a complete composite panel. The honeycomb aluminum panels are featured with lightweight and strong strength, while comparatively cost effective, therefore being the ideal choice under various scenarios including cladding, ceiling, flooring, transportation, marine, etc.

KCP offer various treatments to be applied to the honeycomb aluminum sheets including PVDF, PE, Powder coating, heat transfer printing, etc. to achieve unique aesthetic requirements. With matured production techniques, KCP also offer odd-shape ACM panels with honeycomb core, including curved panels, 90-degree return panels, 3D panels.

KCP’s aluminum honeycomb panel is a sandwich structure consists of two layers of aluminum sheets and aluminum honeycomb core in between. These three layers are bonded by epoxy thermoplastic films. The layers and the films are hot pressed under temperature around 150 degree Celsius to form the finished aluminum honeycomb panels. With the characteristic of elastic and weather resistant, our film-bonded panels can be used under most extreme weather conditions ranging from -40 degree to 80 degree Celsius.

KCP applies thermoplastic adhesive films for lamination of its panels. The thermoplastic film is in solid form under room temperature and melts at around 130 degree Celsius. Comparing to traditional epoxy glue, the thermoplastic film is way higher in elasticity and hence being more weather resistant. It moves along with the substrate under rapid temperature changes without being failure. While it can endure great amount of heat generated by sunlight during hot summers. The thermoplastic film also significantly enhances the production efficiency comparing to epoxy glue.

Alternatively, KCP also provides epoxy adhesive with modified formula which is designated to honeycomb composite bonding. The aluminum sheets are coated with patented epoxy-friendly layer which significantly enhances the bonding strength. Comparing to thermoplastic films, the tensile strength with this combination is over 50% stronger. This suits for both exterior and interior uses and best-fit for those who needs panels with stronger bonding strength.

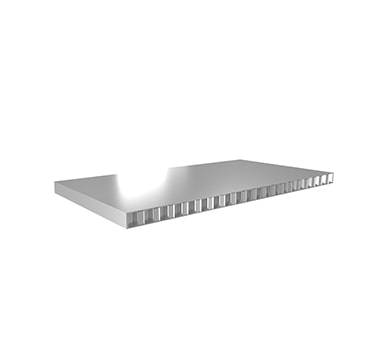

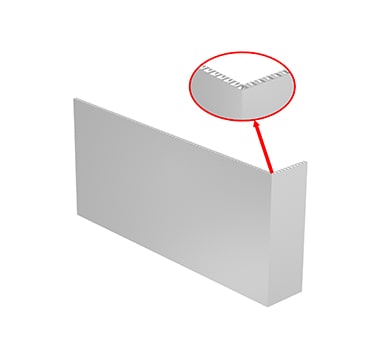

KCP has special tooling and machineries for fabricating odd-shape aluminum honeycomb panels. We are able to offer curved panels, edge-folded panels, one-piece panels with 90-degree returns, double-curved panels, etc. Talk to us today and let us realize your unique design intent with quality aluminum honeycomb panels.